The 10-Second Trick For Bmerry Studio Alaskan Knives

Wiki Article

Some Known Factual Statements About Bmerry Studio

Table of ContentsThe Definitive Guide to Bmerry StudioAbout Bmerry StudioAlaskan Knives Can Be Fun For AnyoneBmerry Studio - QuestionsBmerry Studio Alaskan Knives Things To Know Before You BuyThe smart Trick of Bmerry Studio Alaskan Knives That Nobody is Discussing

At the Arctic Winter Games, gold, silver as well as bronze ulus are offered to athletes. In 2009, a ceremonial ulu existed to the first graduates of the Master of Education and learning program in Nunavut, offered jointly by the College of Prince Edward Island, Nunavut's Department of Education and learning, St. Francis Xavier University and Nunavut Arctic University. This introduction to Rubbing Forging will cover the technical aspects and also regards to what makes a great blade as well as how we create a "Super Blade" with Rubbing Forging. We will quickly review a long time proven and examined methods that produce blades and also edges that constantly out execute others. Our study has developed methods as well as made technical developments that take produced knife-edge efficiency to the next degree.

4%) that generate blades noted for durability, strength, excellent rust resistance and side retention. Blade blades have actually been built for thousands of years, using hand-held hammers, power hammer mills, or some other pressure applying force.

Getting The Bmerry Studio Alaskan Knives To Work

When building is carried out in conjunction with the correct heat treatments termed thermocycling, the crystalline structures of steel, (grains), can be altered. When blades are heated up above the makeover temperature and also held there for a duration of time, the grain frameworks come to be finer, alloyed as well as chemically uniform with the wanted aspects.This is especially the case when there are no "buffers", such as oxides between the grains that will be susceptible to allowing a split to run between the grains in the oxide areas. Furthermore, the knife-edge is much less vulnerable to flaw (boring) when that edge has a hard and fine-grain framework.

How Bmerry Studio Alaskan Knives can Save You Time, Stress, and Money.

The blade edge is brought up to the transformation temperature by the device. As the tool relocations, the blade material is constantly forged.Our blade tests' were done entirely "hands off" to eliminate the human factor as well as insure justness and also create measurable quantitative results (BMerry Studio). SAME GEOMETRY: When screening, examination blades have to be of the EXACT exact same side and also overall geometry. All test blades were ground on an American Siepmann VG3 mill to a.

The final edge was attained using a mechanical fixture that operated on X & Y linear bearings and ground the. 020 edges to a great razor side. The only time in the honing series that human hands touched the blade was the removal of the cable side left by the final sharpening maker.

Our Bmerry Studio PDFs

The second maker is an abrasion examination equipment described as an Edge Retention Tester or ERT and uses a shelf and pinion reciprocating drive system that is computer monitored and configured. A inch manila rope area is fed into the equipment as well as the examination blade cuts the rope and documents the number of strokes as well as the thickness of rope cut with each stroke.

It is far past the extent of this introduction to Friction Creating to report all these outcomes. We will certainly nonetheless, reveal outcomes contrasting Friction Forged blades to "best processed" D2, CPM90V as well as CPMS30 as the S90 and S30 were the steels that came the closest to Rubbing Built blade efficiency.

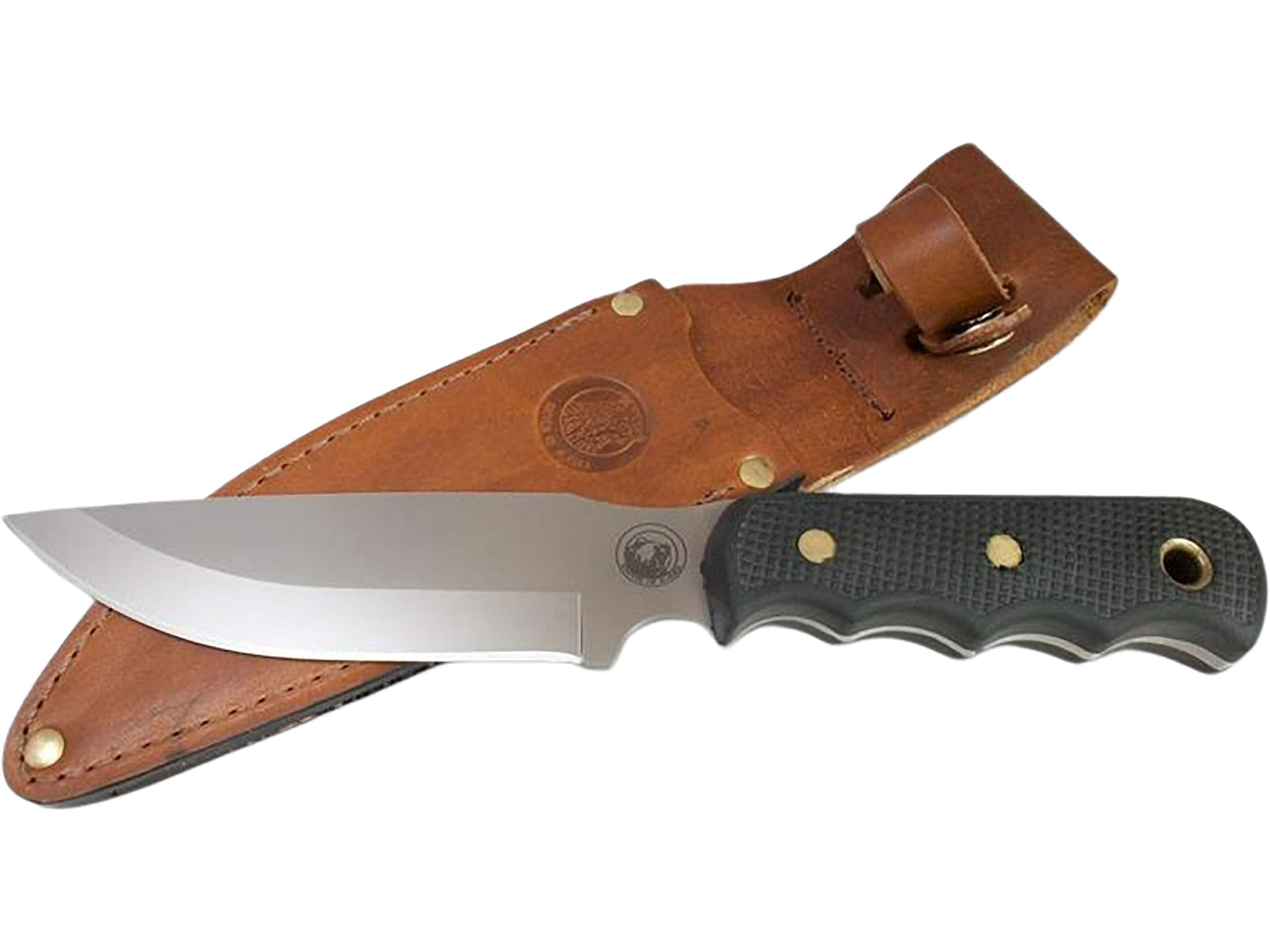

9 times out 10 they 'd attract an overview strongly resembling the KA-BAR copyright fighting/utility knife. As with other well-respected knives,(also on Amazon).

Alaskan Knives for Beginners

Expert Dads still existing KA-BARs to their boys when they full boot camp or avoid for their initial release. The copyright KABAR fighting knife has actually gone to the side of the US Marines and also various other armed pressures since WW2 Pacific movie theater conflicts like,, all the way to the and also The knife was (boring!) as well as jointly made with the (KA-BAR), and also Remarkably, the to please the volumes needed for the war initiative throughout WW2.Obviously, he had shot as well as wounded a grizzly which then charged him as well as knocked his rifle from him. He took care of to draw his blade and also in fact eliminate the upset bear with it. He sent the bearskin as a thankyou to the Union Cutlery Company for making the awesome blade that conserved his life.

It is in fact a Saber grind because the blade only begins tightening concerning half-way down from the spinal column. A level work starts narrowing from the spine itself.

Bmerry Studio Alaskan Knives Fundamentals Explained

has the largest selection of KABAR variations I have actually seen, as well as they lug serrated variations too. I need to admit, the copyright KA-BAR's stacked leather deal with is spectacular. The tan leather balanced Alaskan Knives out by dark grooves creates an eye-catching contrast distinct to the Kabar. In sensible terms, the oval-shaped deal with tapers on either end for extremely natural purchase.

Report this wiki page